NCAB has about 3,650 customers located in 45 countries worldwide. The customer base is far-reaching – for example, the 10 largest customers accounted for 24 % of sales in 2023. The distribution across different countries, industries and types of companies increases diversification and reduces risk.

About half of NCAB’s customers are active in the industrial sector. Typical industrial customers manufacture electronic components for advanced industrial products, which makes quality and reliability important. NCAB also has customers in sectors such as medtech, telecom and heavy vehicles.

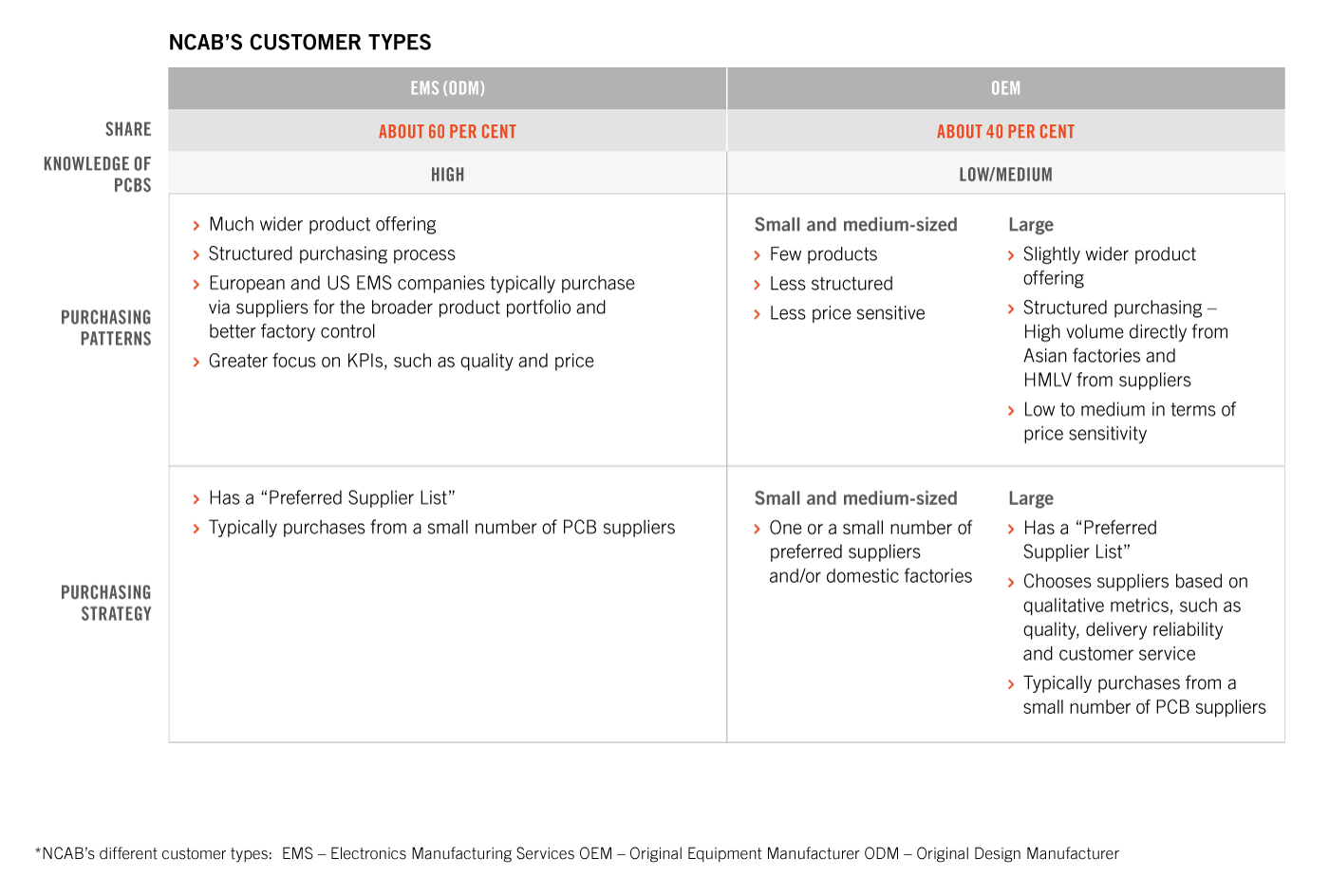

There are two main types of PCB purchasers: Original Equipment Manufacturers (OEM) and Electronics Manufacturing Services (EMS) companies. Normally, an EMS customer demands a wider product mix of PCBs than an OEM customer, as its range of products is wider. EMS customers have greater focus on price than OEM customers, which is explained by, inter alia, that PCBs account for a much larger share of the value of an EMS customer’s product, approximately 8–12% for PCB-As, but also of the lower margins EMS customers typically have. PCBs constitute about 8–12% of the total value of an EMS customer’s end-product and 1–3% of the value of an OEM customer’s end-product.